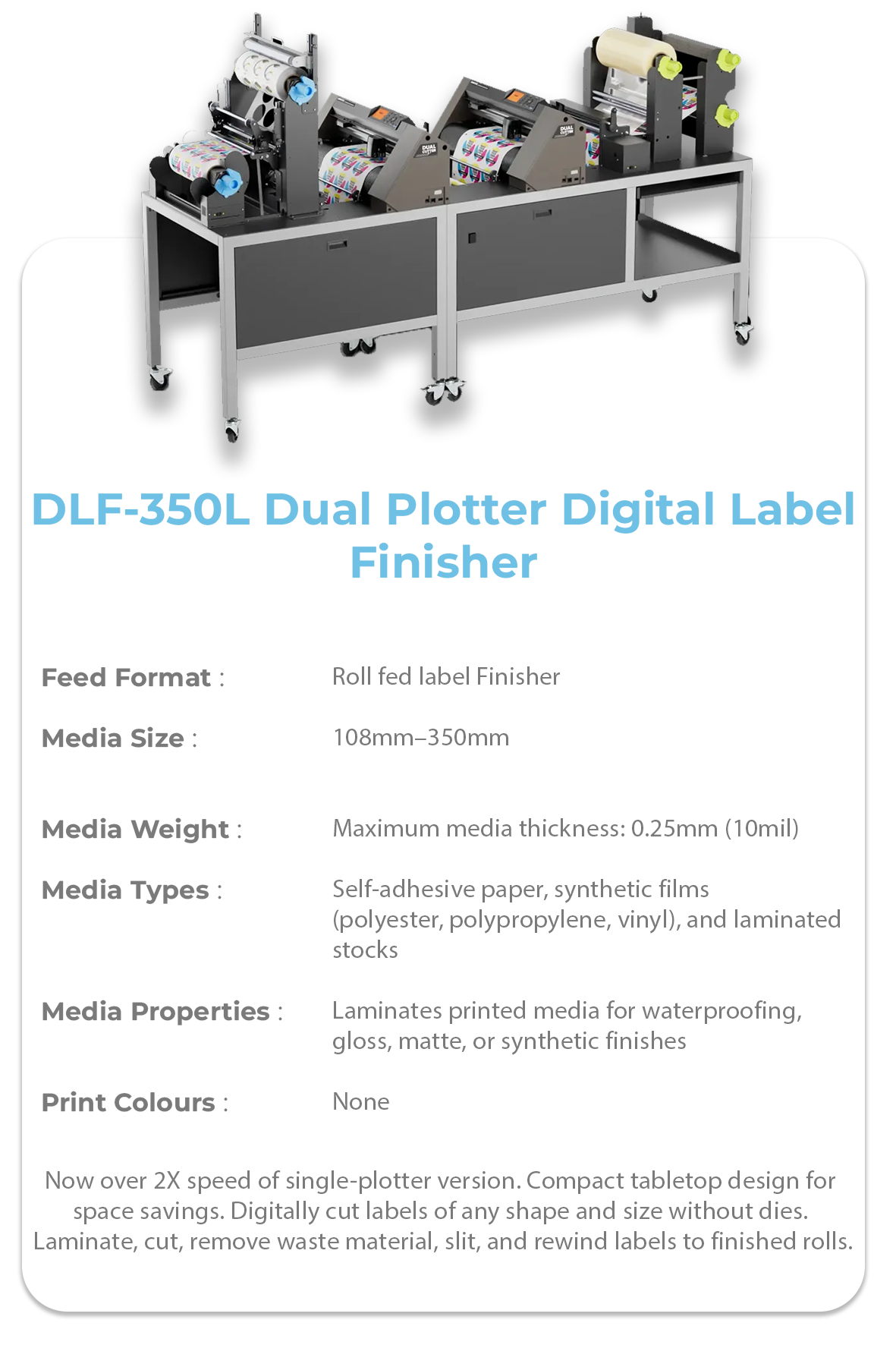

The DLF-350L Dual Plotter Digital Label Finisher integrates unwinding, laminating, contour cutting, waste removal, slitting, and rewinding within a unified process. Designed for on-demand, short-run label finishing, the system incorporates two plotter cutters to optimize cutting efficiency. This feature not only enhances production speed, but also to offers cost-effective operation for businesses looking to manage diverse label finishing demands.

- 2X plotters for increased speed

- Cut from a digital file (no dies)

- 13 in (350 mm) media width

- Ideal for short runs & proofing

Dual Cutting Advantage

Incorporating two plotters, the DLF-350L Dual focuses on efficiency. By dividing the task between the two plotters—movement is minimized, resulting in an optimization of the cutting process. In most cases, this leads to a speed increase of over 2x.

Versatile and Efficient Design

The DLF-350L is equipped to manage a variety of paper and plastic films, delivering precision cuts while ensuring minimal wastage, making it particularly advantageous for short to medium-sized runs.

Economic Benefits

This finisher operates on a digital workflow, removing the requirement for die plates, which translates to operational cost savings. Moreover, it offers the flexibility to modify the label’s shape, size, and quantity as per demand.

Software and Synchronization

The integrated software, paired with CCD cameras, fine-tunes cutting positions. The ease of importing a PDF cutting file further simplifies this process, allowing for on the fly adjustments and quick job changes.

Why Choose Dual Plotter

For diverse layout requirements, the dual plotter’s synchronized functionality offers a distinct advantage over double-head systems, ensuring that both plotters remain actively engaged, optimizing output.

Compatibility

The DLF-350L pairs perfectly with 13-inch (350mm) rolls from printers such as the Afinia X350. This compatibility ensures that labels printed on continuous material can be easily transitioned to finishing with the DLF-350L Dual.

Enhanced Production and Workflow

This model stands out in its ability to accelerate production without compromising on costs. Its state-of-the-art optical sensor is designed to prevent errors, and its user-friendly design promotes time and cost efficiency.

Simplified Processes

The DLF-350L Dual challenges traditional limitations, allowing users to control their label production, reduce wait times, and manage stock. With lamination options and efficient full bleed label production, it encapsulates a holistic approach to label finishing.